Vegetable harvesting module

The COVID-19 pandemic has shown that the systemic dependence of local vegetable production on foreign seasonal labour can exacerbate crises. This has resulted in an increased need for sustainable automation solutions. The vegetable harvesting module for multi-purpose field robots (GEM) developed in this project closes this gap by reducing the need for monotonous and physically strenuous field labour by fully automating the harvesting process. As a result, higher yields are achieved on the field with less effort.

Hardware development

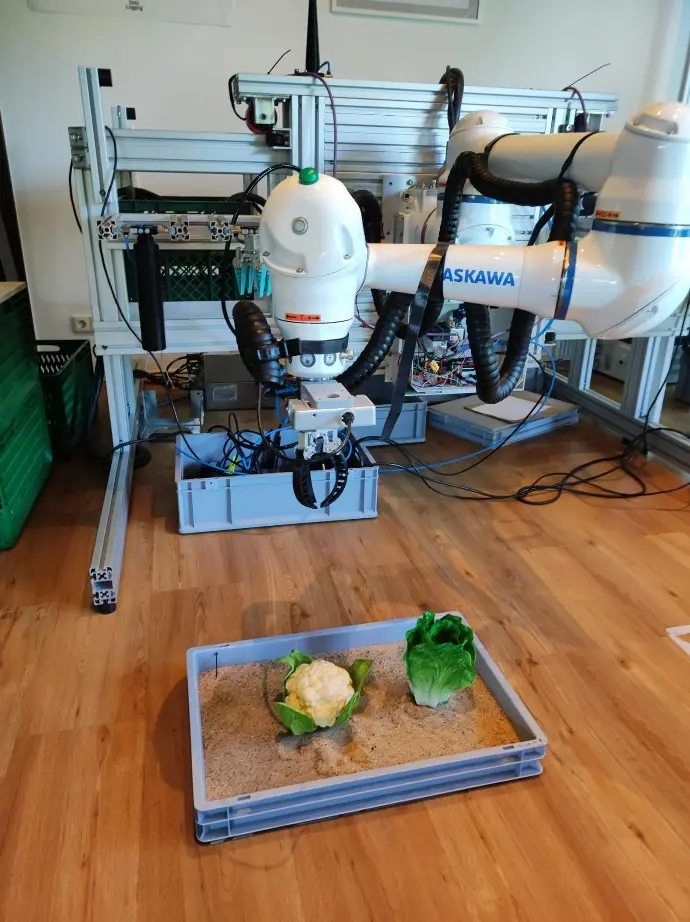

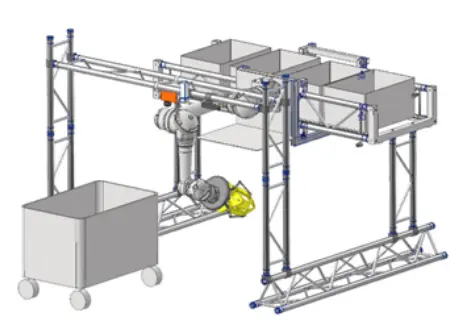

The vegetable harvesting module is being developed and tested in three different environments. The robot test stand in the laboratory, the illustrated laboratory setup of the overall module and as part of the system integration at DAVEGI.

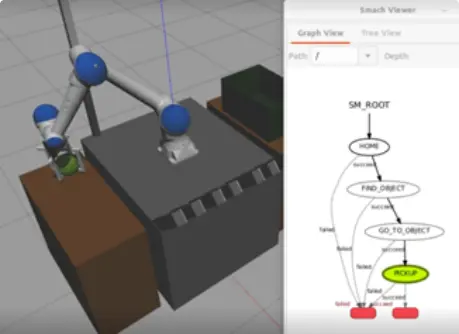

Software development

All required automation processes are developed and tested in simulation environments before they are transferred to the real system.

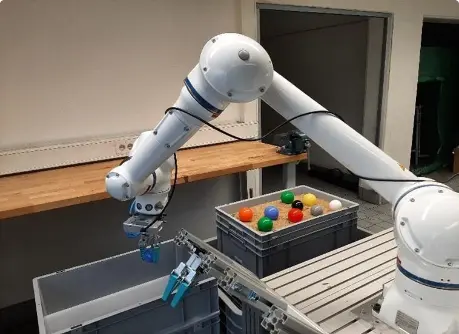

Laboratory tests

Tests are carried out in the laboratory, sometimes also on plastic balls, in order to be able to continuously improve the processes regardless of plant availability.

Plant recognition

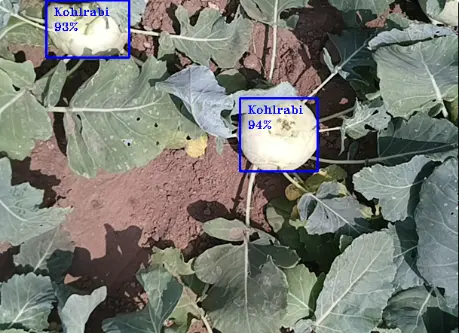

The key factor for a successful harvest is plant recognition. To this end, images are continuously recorded and then used for plant recognition using machine learning methods.

System integration and field test

The final step is system integration and field testing on the real system. AI.Land GmbH is pursuing the modular use of the harvesting module in ETAROb and DAVEGI.

Supported by

Vegetable harvesting module

VHM (Vegetable Harvest Module) aims to research and develop a multifunctional harvesting process tool for various vegetable crops in order to relieve farmers in their search for qualified seasonal labour and to secure the food supply in times of pandemic. The vegetable harvesting module can be combined with conventional agricultural machinery. Currently, fully automated cultivation systems are only available in greenhouses, where mainly herbs and leafy vegetables are produced. Indoor farming is not economically viable due to high energy costs and a limited nutrient balance. Over 98% of the world's vegetables are grown outdoors, which is more efficient in Germany if dependence on cheap labour is reduced. Numerous studies are being conducted and concepts trialled in the field of science. Our ETAROB is a good cross-sectional example of this.

VHM supports the development of fully autonomous agricultural systems with a focus on tool technology. The yield is increased through selective methods. This means that more can be grown on less arable land. The target is: Iceberg lettuce, white cabbage, red cabbage, broccoli, kohlrabi, cauliflower and celery.

Field robots open up a multitude of synergy effects. Although the transfer to agricultural practice is still very recent, an increasing number of precision tools will have a resounding effect on climate protection, resource conservation and biodiversity.