DAVEGI

More than automation: AI that touches vegetables

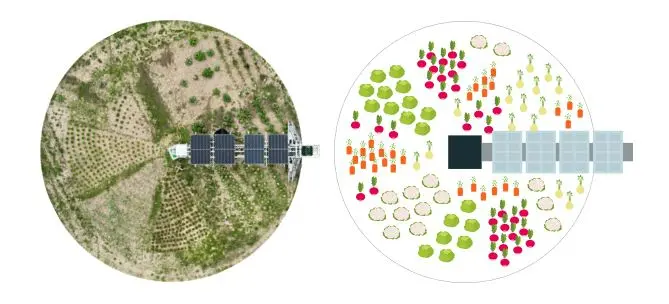

DAVEGI is an intelligent field robotics system that redefines vegetable growing. With precise sensor technology and robotics, each plant is individually recognised, cared for and harvested. Freshly assembled vegetable boxes are produced directly in the field and in a variety of mixed cultures, which are delivered directly from the field to your home. More organic is not possible!

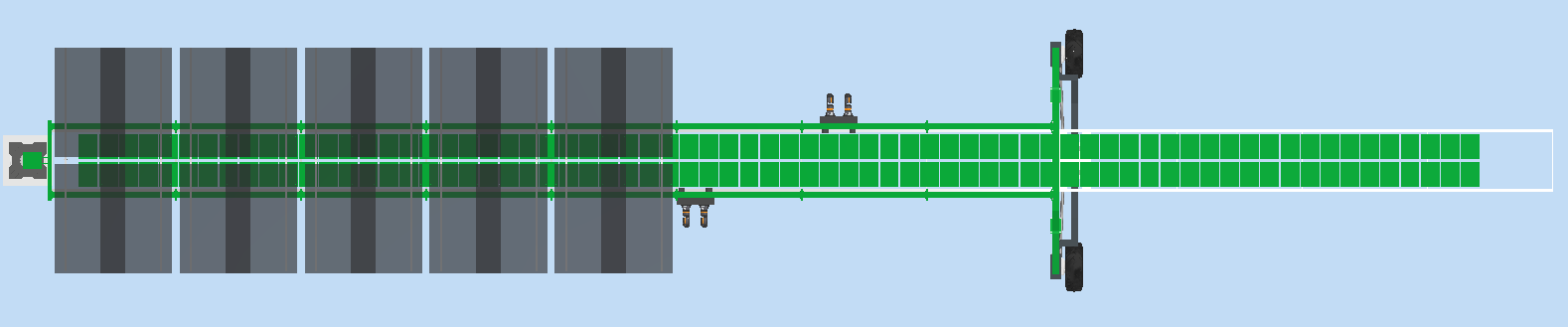

DAVEGI is the world's first fully autonomous agricultural system that brings fresh vegetables directly from the field to the consumer. With embodied AI, precise robotics and a stationary traverse system, DAVEGI takes over the entire process: cultivating, monitoring and harvesting plants and packing them into crates on site - all in a single, closed cycle. This radically shortens value chains, reduces costs and makes sustainable, regional food production economically attractive. Whether for farmers, local authorities or institutions - DAVEGI transforms 2,500 m² of space into a high-yield, climate-friendly vegetable farm: efficient, profitable and future-proof.

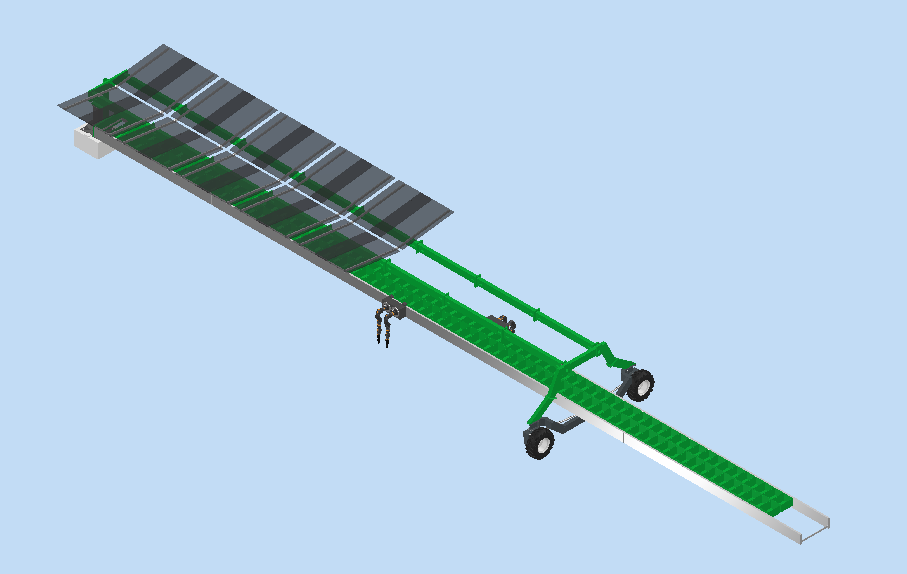

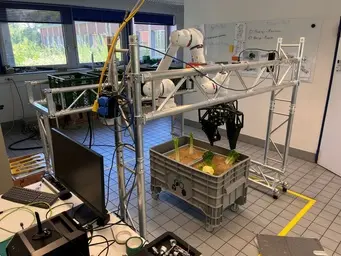

The system

DAVEGI works on a rotating traverse system that runs over the field like a carousel. As a result, there are no heavy tracks in the soil, which would otherwise impair fertility. At the same time, the central base station enables an efficient supply of water and energy. Two slides on the traverse can travel back and forth, reaching every plant. A torso with two arms and hands cultivates each vegetable plant individually and can care for them, whether kohlrabi, lettuce or pumpkin, free them from slugs and weeds. The second carriage has a soil auger and an irrigation system. From sowing to harvesting, DAVEGI takes care of every process.

Vollautomatisiert

Biodiversität

Ökonomischer Nutzen

Einzelpflanzenkultivierung

75% Konvektionierte Gemüsekiste

25% Gemischte Gemüsekiste

Concept

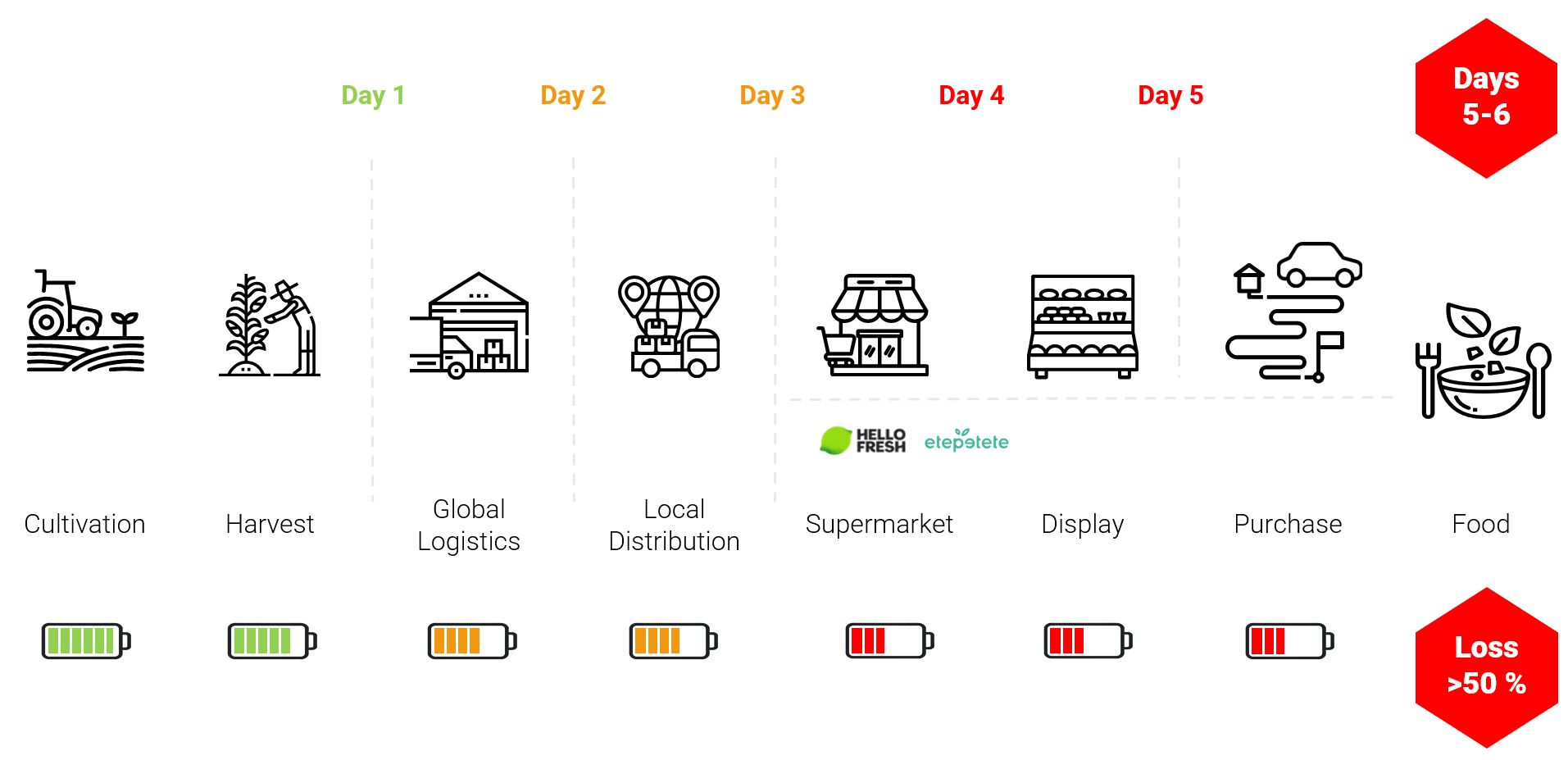

Problem: Long value chain

Today, fresh vegetables often travel a long way from the field to the plate. After the harvest, they are distributed via central packing stations, cold chains and wholesalers before arriving at the supermarket or restaurant. Each of these steps causes costs, transport emissions and quality losses - up to 30% of the harvest is lost in the process. At the same time, farmers only receive a small portion of the sales price, while consumers pay higher costs for less fresh produce.

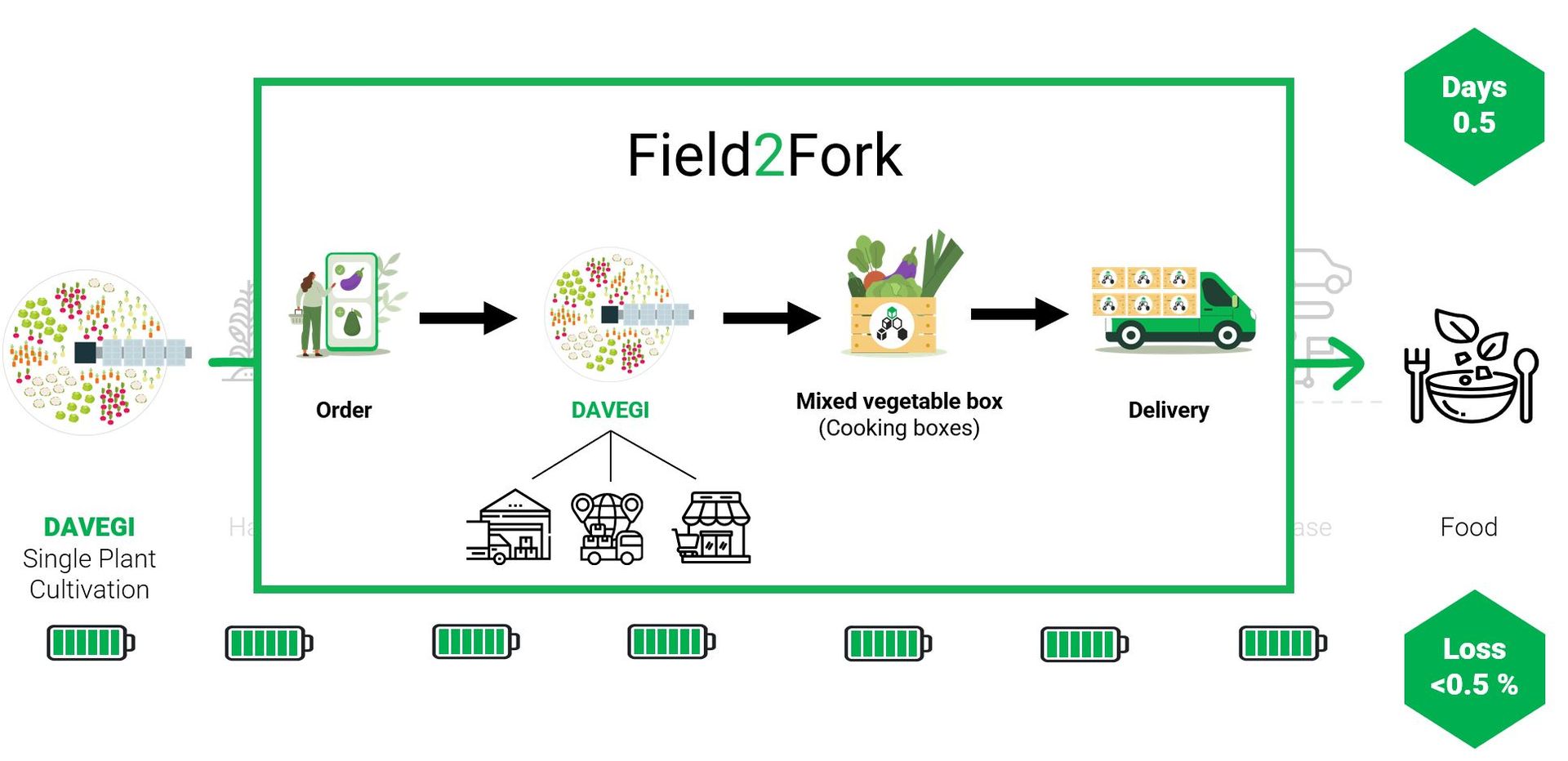

Solution: DAVEGI - Field2Fork concept

DAVEGI breaks up the long value chain by growing, caring for, harvesting, sorting and packaging directly in the field. The finished vegetable boxes can be delivered to customers without any detours or cold chains. This Field2Fork principle drastically reduces costs, transport routes and losses - and enables fresh, regional vegetables at a price that is attractive to producers and consumers alike.

Mixed vegetable box

100 boxes per day

- Selling price 10€ - 25€ per box

- 250 sales days (working days)

DAVEGI

25 metres (25,000 plants)

- 2,500 square metres of space

- 4 cultivation cycles of 25,000 plants per year

- 100,000 vegetable plants in one year

- 1€/ kg

Nutrition Circle

Teleoperation

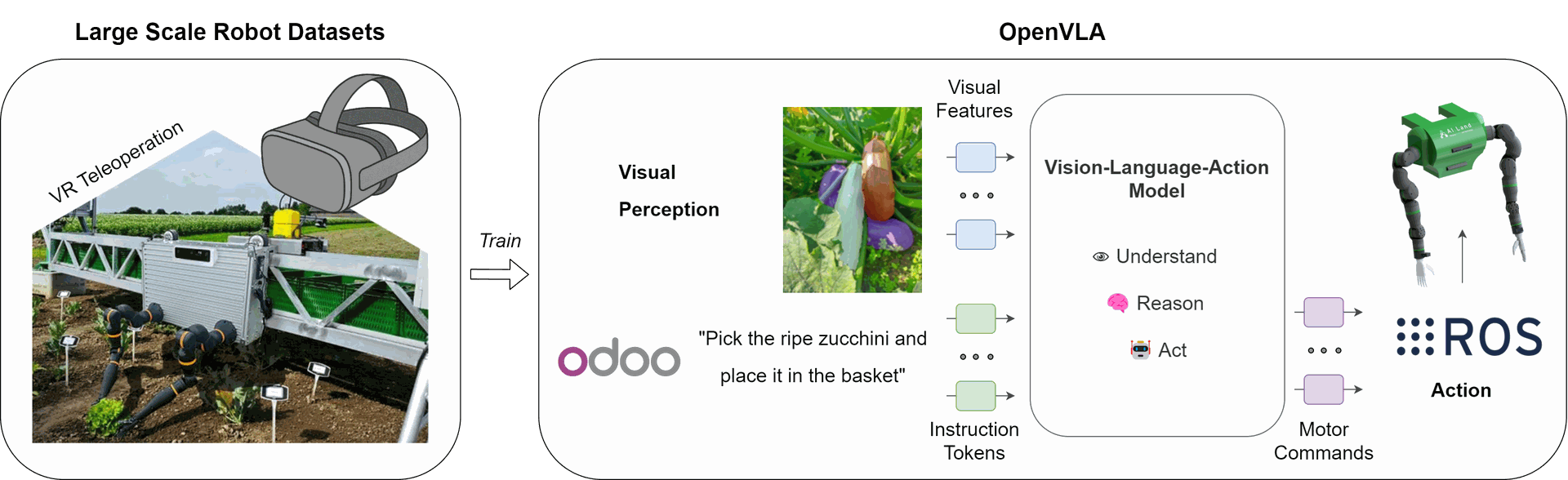

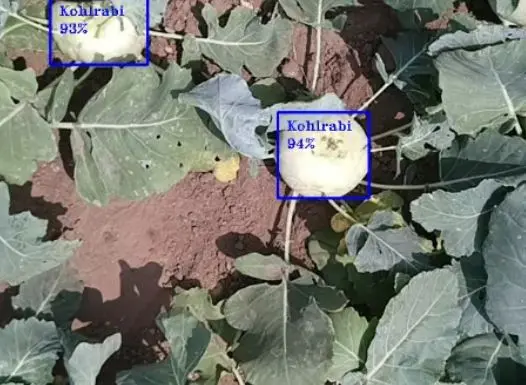

DAVEGI learns through teleoperation: human operators control the robot arms and hands in real fields and generate valuable training data in the process. This data is used to further develop the system's embodied AI. An AI that not only sees and makes decisions, but also interacts with real plants. Step by step, DAVEGI will be enabled to recognise, grasp and harvest independently, working ever more precisely and efficiently.

Teleoperation is the remote control of a robot or machine. Imagine controlling a remote-controlled toy car, but with much more precise and complex movements. In the DAVEGI project, this means that humans control the robotic arms and hands in real time to perform certain tasks, such as harvesting vegetables.

Training the DAVEGI robot via teleoperation is a crucial step on the way to full automation. Instead of programming the robot from scratch, human operators show it how to perform certain tasks.

- Learning process: The movements and actions that are remotely controlled by people are collected as data.

- AI models: This data serves as the basis for training special AI models, the so-called Vision-Language-Action (VLA) models.

- Autonomy: As soon as these models have been trained with sufficient data, the robot can perform the tasks it has learnt independently. It then understands how to react to visual cues (e.g. the colour of a ripe courgette) in order to perform the correct action (e.g. picking).

The aim is to train the DAVEGI so that it no longer requires remote control by humans, but can work independently and autonomously in the field.

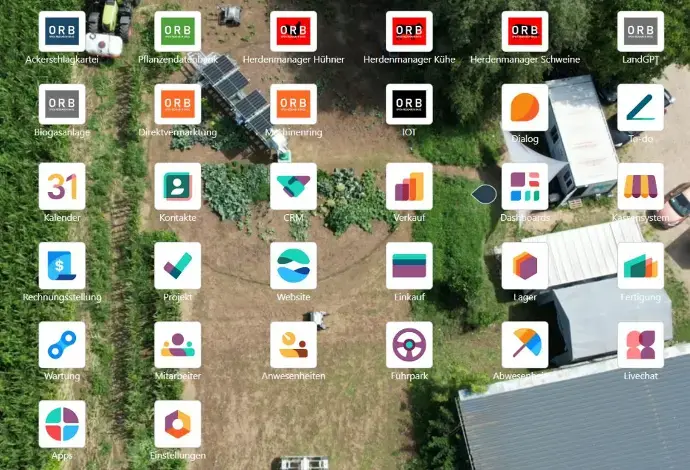

We work with the farm management system of the Open Research Base, which uses Odoo and Ros. All data is processed and stored here. If you want to find out more, take a look at the world of open innovation Learn more about ORB gGmbH

Vision-Language-Action (VLA) models are based on human demonstrations acquired through teleoperation in virtual reality (VR). The model processes multimodal sensor inputs and task instructions provided via the Odoo ERP system and is thus able to generate motorised actions, such as picking a ripe courgette, overlaid with visual cues such as a mask.

Solar operation

DAVEGI is 100% solar-powered and works self-sufficiently - even at night. The integrated base station has a battery storage unit that temporarily stores surplus energy and thus enables continuous operation. Operation is emission-free, independent of the power grid and ideal for regions without infrastructure. The stored energy can also be used to charge electric delivery vehicles. Harvesting at night in cool temperatures also improves the freshness and shelf life of the vegetables.

Ecological and economic advantages

- Increased efficiency: DAVEGI can increase the efficiency of vegetable cultivation by more than 50 % compared to conventional methods, both ecologically and economically.

- Optimum utilisation of space: While conventional AgriPV systems lose arable land due to static shading or the height required for machinery, DAVEGI can utilise the land potential almost completely. The turnover per hectare in vegetable cultivation can increase fivefold.

- Increased earnings: As the PV system moves across the arable land, constant static shading is avoided, which can otherwise cause crop losses of 20-30 %.

Technical and operational advantages

- Support for compact agricultural robotics: The PV support structure also serves as a rail for compact agricultural robots. This eliminates the need to raise the PV systems very high, which simplifies construction and reduces costs.

- Fully automated and precise processes: DAVEGI kann alle Anbauprozesse – von der Bodenbearbeitung bis zur Ernte – präzise und individuell ausführen. Dazu gehören:

- Selective sowing, fertilisation, irrigation and weed control

- Ecological plant protection

- Spot tillage

Self-sufficiency and transparency

- Energy self-sufficiency: Thanks to local energy generation by AgriPV modules and an integrated battery storage system, the vegetable farm is energy self-sufficient.

- Freshness and variety: The system can put together fresh vegetable boxes every day.

- High transparency: An app provides customers with a high level of transparency regarding the origin and cultivation of the products.

Direct marketing - Field2Fork

DAVEGI packs directly in the field without a warehouse, intermediary or cold chain. Each vegetable box is filled individually according to the customer's wishes, some are put together in a colourful mix and delivered within a few hours of harvesting. This saves transport routes, reduces losses and guarantees maximum freshness directly on the plate.

DAVEGI is revolutionising direct marketing and the Field2Fork concept (from field to fork) by optimising the value chain for farmers and consumers alike. The system enables efficient, local production that strengthens direct contact between producers and consumers.

The DAVEGI system is able to pack the harvested vegetables directly in the field. This eliminates middlemen and long transport routes. As the harvest is demand-orientated, the goods are delivered directly from the field to the customer – It couldn't be fresher.

For farmers, this means a higher margin and greater independence. They can sell their products directly to local customers such as supermarkets, restaurants or via their own farm shop. For consumers, the Field2Fork concept guarantees unprecedented freshness, maximum nutrient density and complete transparency about the origin of their food. At the same time, the short supply chains drastically reduce CO₂ emissions and packaging waste, making the concept not only economically but also ecologically sustainable.

Sustainability

DAVEGI stands for a change in agriculture. The system has a threefold positive impact on the environment, the economy and society: it enables sustainable, local and at the same time economically successful food production.

DAVEGI makes the difference

DAVEGI pursues a holistic approach that has a positive impact on the environment, the economy and society.

Environment and climate: A new way of cultivation

Thanks to single-plant cultivation, water and nutrients are applied precisely and according to need. This reduces the need for chemicals and protects the soil quality. The system is completely solar-powered, does not use fossil fuels and can even feed surplus energy into the local power grid. In-field packaging and the use of reusable crates reduce transport losses by up to 90 % and packaging waste by up to 80 %.

Economic benefits and social impact

DAVEGI makes regional vegetable growing attractive again. With operating costs of just 1 € / kg, farms can become independent of middlemen and reduce their dependence on seasonal labour.

At the same time, DAVEGI strengthens the local food supply. Manual labour is transformed into highly skilled jobs in the fields of robotics, software development and AI. The "Shared Urban Gardening" model also enables schools or groups of citizens to participate in cultivation, which not only promotes local food production but also teaches digital skills.

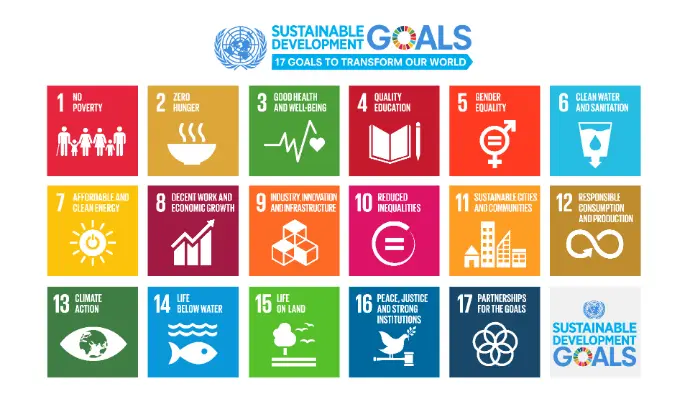

DAVEGI and the UN Sustainable Development Goals (SDGs)

Das System leistet einen direkten Beitrag zu verschiedenen globalen Nachhaltigkeitszielen:

SDG 1 – No poverty: Through efficient, local production, DAVEGI lowers barriers to entry and supports economic participation.

SDG 1 – No poverty: Through efficient, local production, DAVEGI lowers barriers to entry and supports economic participation.

SDG 2 – Zero hunger: Increases productivity in small areas and enables a reliable supply of vegetables.

SDG 2 – Zero hunger: Increases productivity in small areas and enables a reliable supply of vegetables.

SDG 6 – Clean water: Precise irrigation and fertilisation reduce water wastage and the use of chemicals.

SDG 6 – Clean water: Precise irrigation and fertilisation reduce water wastage and the use of chemicals.

SDG 7 – Clean energy: The system is completely solar-powered and contributes to regional energy resilience.

SDG 7 – Clean energy: The system is completely solar-powered and contributes to regional energy resilience.

SDG 8 – Decent work: DAVEGI creates new, well-paid jobs in the STEM fields and agricultural science.

SDG 8 – Decent work: DAVEGI creates new, well-paid jobs in the STEM fields and agricultural science.

SDG 11 – Sustainable cities: Short supply chains, lower CO₂ emissions and less packaging waste ensure a clean environment.

SDG 11 – Sustainable cities: Short supply chains, lower CO₂ emissions and less packaging waste ensure a clean environment.

SDG 13 – Climate protection: Local, off-grid production and the reduced use of operating resources significantly reduce the ecological footprint.

SDG 13 – Climate protection: Local, off-grid production and the reduced use of operating resources significantly reduce the ecological footprint.

Measurable success (based on current validations)

- Up to 70 % water savings through demand-orientated irrigation

- Up to 25 % higher yields thanks to mixed crops and continuous cultivation

- Up to 90 % less post-harvest losses thanks to demand-orientated harvesting

- 100 % fossil-free operation thanks to integrated solar energy

- Up to 80 % less packaging waste thanks to reusable box logistics

Our references

Partners, sponsors, prizes and co-operations

DAVEGI in development

Idea

Multi-purpose agricultural robot for vegetable cultivation. Development at Aachen University of Applied Sciences.

ETAROB

Multi-purpose agricultural robot and cornerstone for the DAVEGI

Robotics and AI

Laboratory tests with plastic balls

Collection of plant data

Machine learning for plant recognition

System integration and field test

Harvesting module in the field

DAVEGI

Bridge technology with base station for semi-autonomous operation

Hard- and Software

Collecting data for plant recognition and further development of the DAVEGI

Teleoperation

Focus on arms and hands instead of an interchangeable tool system

Discover DAVEGI - the first field robotics system for vegetable growing

If you would like to find out more about prices and possible applications, please contact us directly.